8. Open source hardware: from fibers to fabric#

Amazing multi-processing machine

IN DEPTH INFORMATION CAN BE FOUND HERE : MPM

This week was a great experience! The assignment was made as a group with all six of us: Irene; Weeeendy; Jessica; Teresa; Scarlett; and myself. On the first day we started brainstorming around all the ideas we had, discussed everything while already developping some of the best ideas and we finally agreed on doing an ‘incubator’ with several functions : from Mycelium growing, to making Kombucha, and even drying fruit leather.

Organisation and start!#

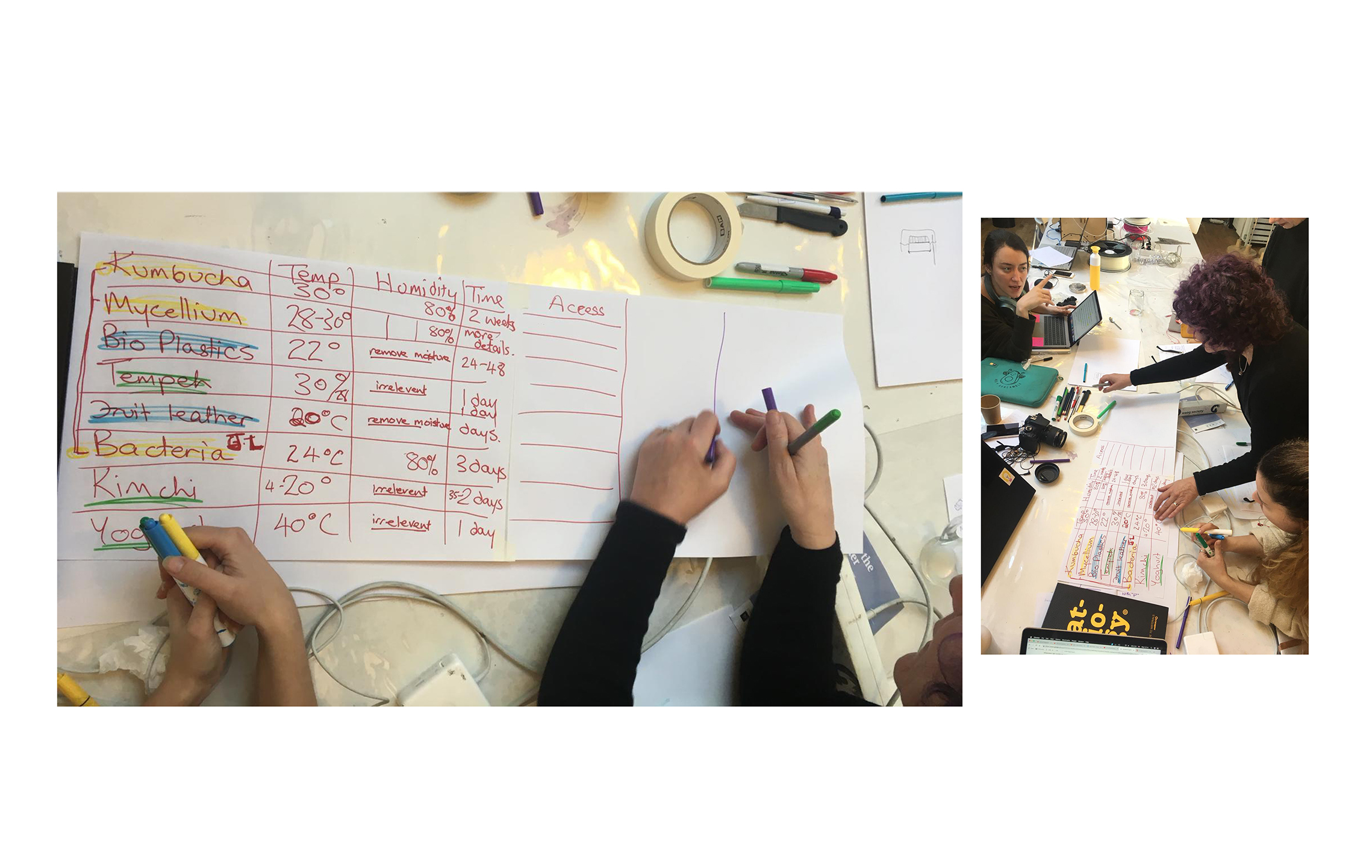

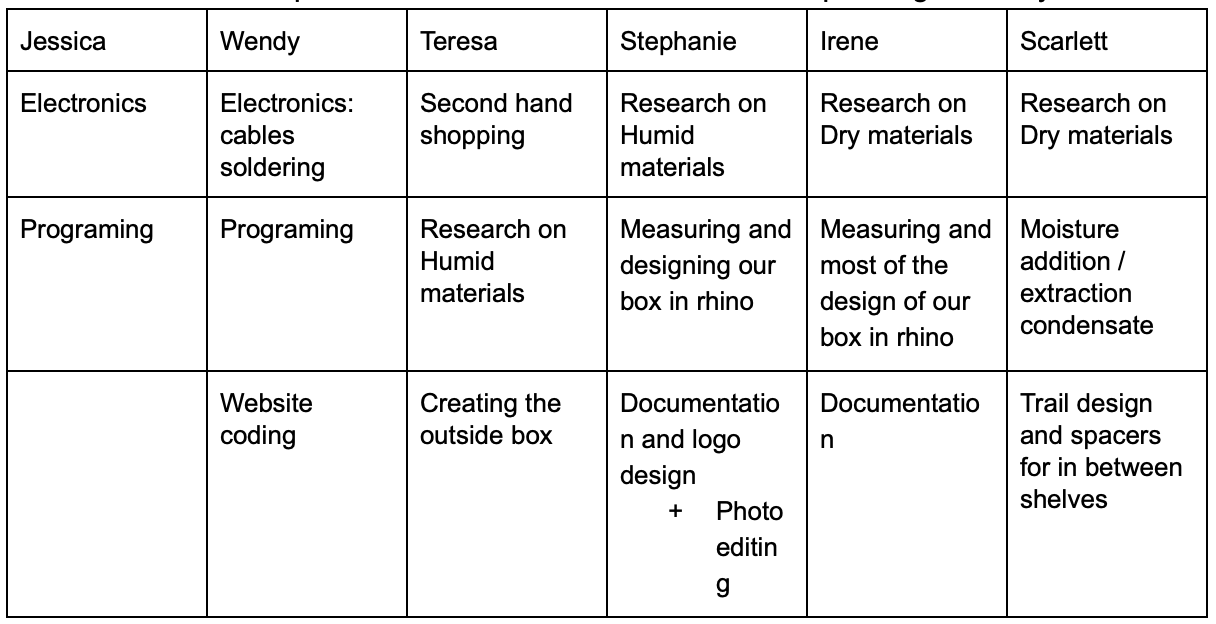

Because we wanted this machine to have several functions, we needed first of all to gather some information and do quite some research on each process ( temperature, humidity level, time of the ‘incubating’ process,..). As well as, starting to do research on the electronic devices and pieces we would possibly need. So we split the team in three groups :

- Electronics group : Jessica and Wendy

- Research groups : Irene & Scarlett on the drying processes and Teresa & Me on the processes needing humidity

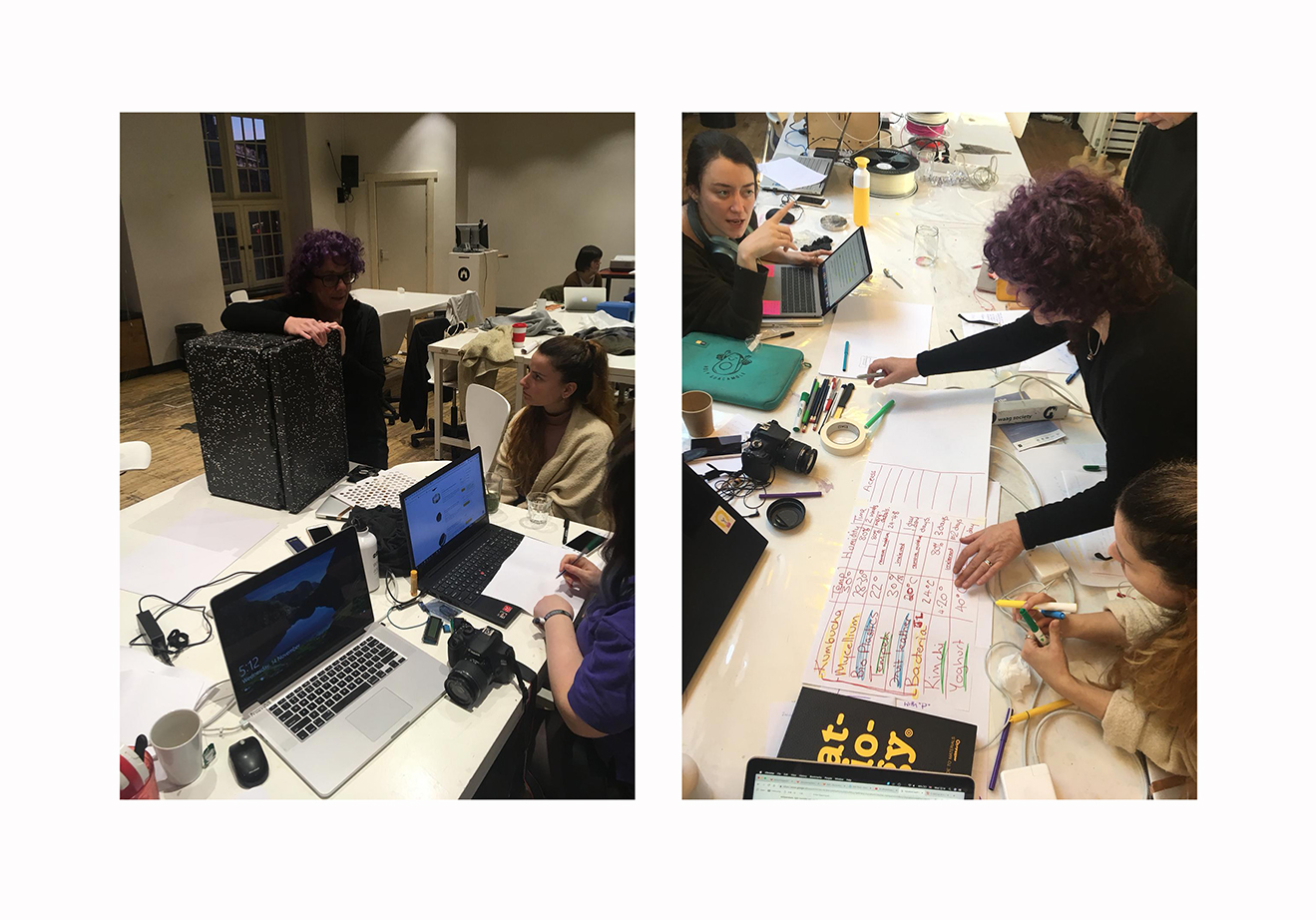

Also, we agreed on having morning meetings to discuss the progress on the works and to have everybody informed of the issues/decisions that has been made or were needing to be made as a team.

Our meetings were always very nice and productive.

We continued to put everyone into working on the project while considering each member’s skills.

A quick planning and listing has been made during one of the morning meetings :

Start of the design#

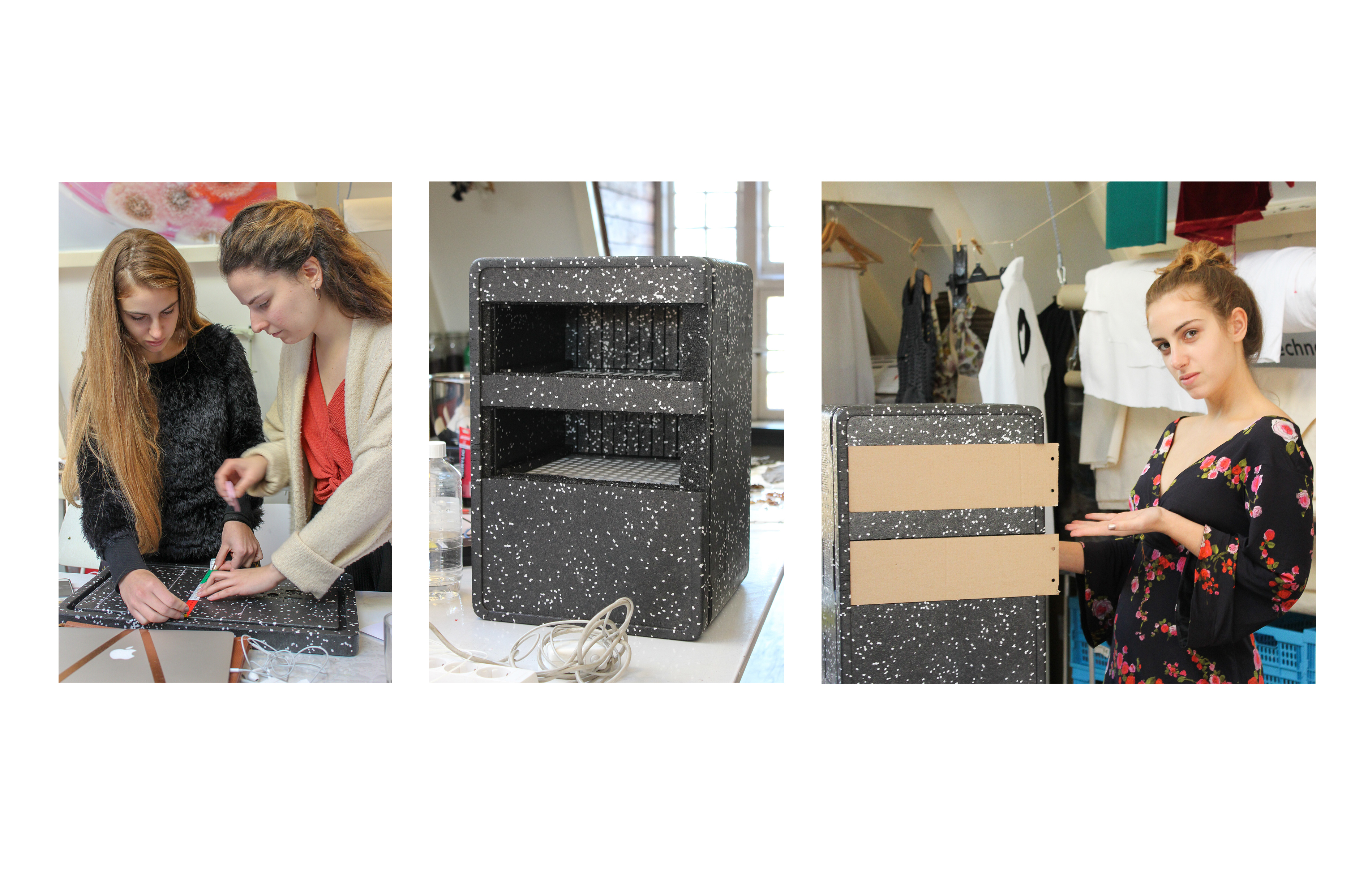

After the research, I started with the design and customization of the box and it’s elements together with Irene, Teresa and Scarlett. Irene and I created a Rhino file with the 3D model of the actual box. ( Well I took all the measurements and Irene translated them onto Rhino3D ). I figured out it would be a nice idea to have two openings on the lid part to axcess the inside of the box, preventing from always opening the lid.. Irene and I took the measurements and prepared the lid to give it to Wendy for the milling job ( cause she’s the Milling-ladyboss ). After the milling of the windows by Wendy, I went for laser-cutting the sliding windows after receiving the file from Irene.

After only three days we had already accomplished a lot and this is what we got so far :

Logo design#

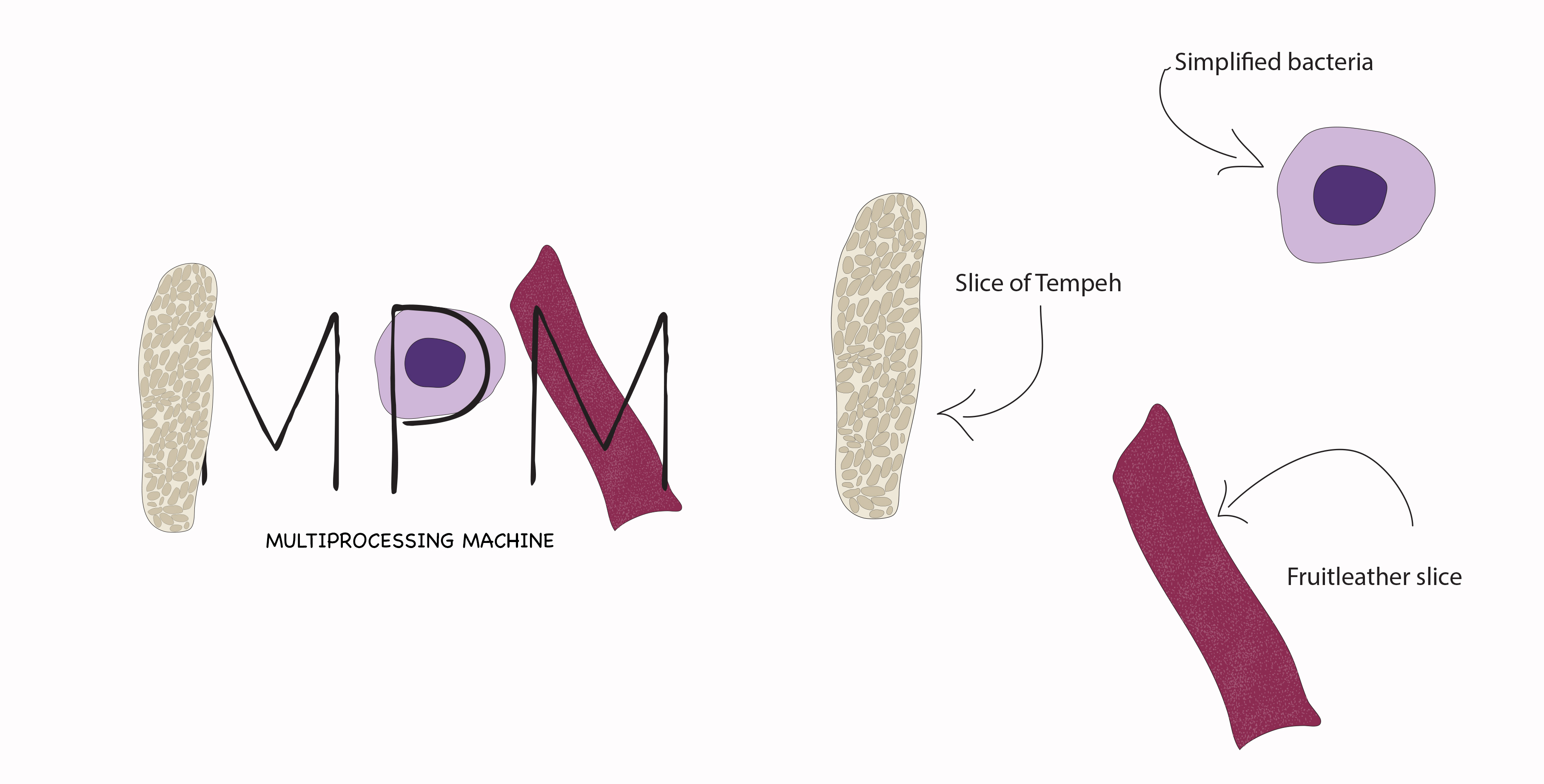

On the last day and a half I responsible for the documentation on the group page of the MPM, editing all of the photos and I got to design the Logo for our machine.

I only had a few hours for the logo design and had to test several typographies and ask the team’s opinion, continuing with the design and ended up with a cute, colorful and fresh logo.

-> typo choices

-> Brief explanation of the design

The Team#

A big thank you to the team for this amazing and fun experience !